Vertically integrated valve manufacturing, in-house API 10F flow loop testing, and full product traceability ensures our float equipment can be trusted to perform.

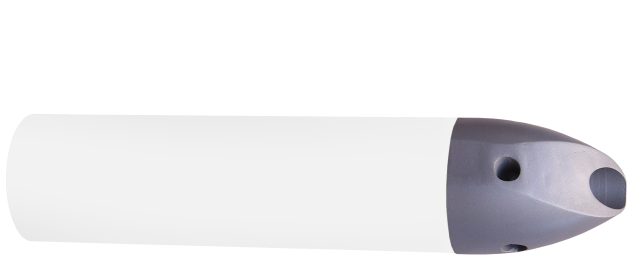

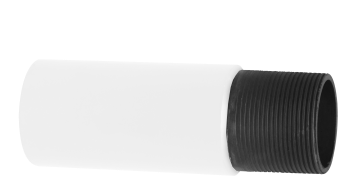

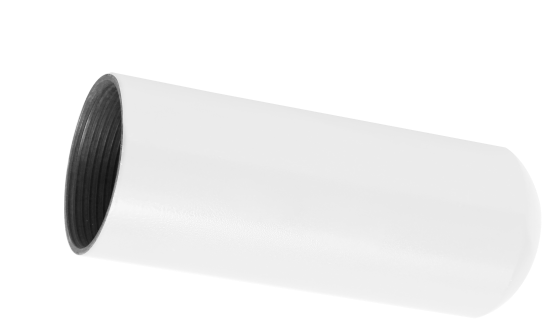

A plunger style valve is used in float equipment for applications where high flow rates, lost circulation materials (LCM) and/or extended flow rates are encountered. The valve has a nitrile coated phenolic plunger for wear resistance and sealing of the valve. Available in sizes 2-3/8” (63mm) to 40” (1016mm) other features include.

At Integrity Downhole, we harness our experience to deliver downhole equipment that not only meets but exceeds the highest industry standards.

Dedicated to driving efficiency and lowering costs, our rigorously tested products ensure reliable wellbore integrity and zonal isolation.

With a commitment to integrity and excellence, ID is building a legacy.

Our unwavering dedication to quality and performance is evident in every product we create and every relationship we develop. Learn more about our journey, values, and the people behind our products.

Our float equipment, centralizers, and casing accessories are engineered to outperform through advanced design and rigorous testing.

Integrity Downhole delivers equipment that is not only dependable but also cost-effective, making us a leader in the rapidly evolving energy industry.