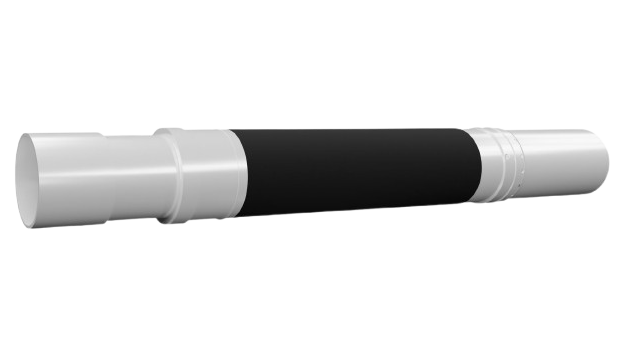

External Casing Packers

External Casing Packers (ECP) are primary cementing and zonal isolation packers designed with inflatable pack-off elements to provide an annular seal between casing and wellbore.

ECP Assemblies are hydraulically operated. Applied casing pressure initially opens the packer inflation valve. A secondary closing valve shears to trap inflation fluid in the packer once the preset shear value has been reached.

ECP Assemblies are available for most casing sizes, weights, grades, and thread connections. ECP Packer Element expansion capabilities and pressure ratings are shown in the Differential Pressure Curves. Packer Element are available in 1, 3, and 6 m lengths.

Features and Benefits

The following features were designed into ECP Assemblies, making it the premium product in its class.

- Effective Zone Isolation – Seals wellbore between zones either as a backup for the cement or as the primary seal

- Protects Cement – Channeling is prevented by effectively blocking movement of gas or fluid. Cement is allowed to set undisturbed.

- Protects Sensitive Formations – Cement is isolated from sensitive formations, minimizing formation damage.

- Allows Cementing of deep wells without damaging lower zones – Deep wells may be stage cemented to protect lower zones from long cement columns

- Proper Cement Distribution – The ECP centralizes casing in the wellbore to ensure even cement distribution around the casing

- Dual locking shear valves in series – Effectively traps inflation

- Top Mounted Valve Housing – Senses true annulus pressure for consistent accurate inflation

- Field Adjustable Pressure Settings – ECP Assemblies are supplied with shear pin cards. External Access is provided for adjusting pressure settings

- Mandrel Size, Weight, Grade, and Thread Connections are same as casing string – Matches internal collapse, internal burst and body yield.

Casing Size | Maximum OD | Size Class | ||||

Standard Clearance | Special Clearance | |||||

mm | Inch | mm | Inch | mm | Inch | |

60.33 | 2 3/8 | 91.95 | 3.62 | 86.11 | 3.39 | 060 |

73.03 | 2 7/8 | 107.95 | 4.25 | 92.71 | 3.65 | 073 |

88.90 | 3 1/2 | 120.65 | 4.75 | 109.22 | 4.30 | 089 |

101.60 | 4 | 133.35 | 5.25 | 127.00 | 5.00 | 102 |

114.30 | 4 1/2 | 146.05 | 5.75 | 141.28 | 5.56 | 114 |

127.00 | 5 | 158.75 | 6.25 | 151.13 | 5.95 | 127 |

139.70 | 5 1/2 | 177.80 | 7.00 | 165.10 | 6.50 | 140 |

146.05 | 5 3/4 | 184.15 | 7.25 | 171.45 | 6.75 | 146 |

168.28 | 6 5/8 | 201.42 | 7.93 | 193.80 | 7.63 | 168 |

177.80 | 7 | 209.55 | 8.25 | 203.20 | 8.00 | 178 |

193.68 | 7 5/8 | 228.60 | 9.00 | 222.25 | 8.75 | 194 |

219.08 | 8 5/8 | 260.35 | 10.25 | 254.00 | 10.00 | 219 |

244.48 | 9 5/8 | 285.75 | 11.25 | 279.40 | 11.00 | 244 |

273.05 | 10 3/4 | 323.85 | 12.75 | 314.45 | 12.38 | 273 |

298.45 | 11 3/4 | 349.25 | 13.75 | 339.85 | 13.38 | 298 |

339.73 | 13 3/8 | 400.05 | 15.75 | 381.00 | 15.00 | 340 |

406.40 | 16 | 463.55 | 18.25 | 454.15 | 17.88 | 406 |

473.08 | 18 5/8 | 558.80 | 22.00 | 546.10 | 21.50 | 473 |

508.00 | 20 | 584.20 | 23.00 | 571.50 | 22.50 | 508 |

558.80 | 22 | 635.00 | 25.00 | 609.60 | 24.00 | 558 |

At Integrity Downhole, we harness our experience to deliver downhole equipment that not only meets but exceeds the highest industry standards.

Dedicated to driving efficiency and lowering costs, our rigorously tested products ensure reliable wellbore integrity and zonal isolation.

With a commitment to integrity and excellence, ID is building a legacy.

Our unwavering dedication to quality and performance is evident in every product we create and every relationship we develop. Learn more about our journey, values, and the people behind our products.

Our float equipment, centralizers, and casing accessories are engineered to outperform through advanced design and rigorous testing.

Integrity Downhole delivers equipment that is not only dependable but also cost-effective, making us a leader in the rapidly evolving energy industry.