We lead with integrity, delivering measurable value to our customers and partners. Integrity Downhole (ID) prioritizes efficiency, quality, and disciplined capital allocation to produce high-performing, cost-effective products, all without compromising the client experience.

Our products are manufactured in API Q1, API 5CT, and ISO 9001:2015 qualified facilities. We back our solutions with verifiable testing data, ensuring that our products consistently comply with the requirements and standards of API 10D 7th Edition, API 10D2, API 10TR5, API 10TR6, and API 10F.

Monthly Production Capacity

600+

Float Equipment

All sizes 4 1/2" to 36"35000+

Centralizers

All sizes- 1-2/3" to 36"70000+

Stop Collars

All sizes- 2-3/8" to 36"300+

Plugs

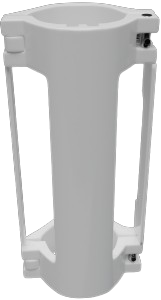

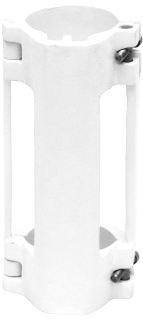

All sizes 4-1/2" to 20"ID’s centralizers are designed and manufactured to assist casing running and cementing. Proper selection and arrangement are vital factors in successfully placing and supporting the casing string in the wellbore, enhancing mud removal and providing zonal isolation. Zonal isolation is a key contributor in maximizing the economic value of a well by optimizing production and minimizing costs.

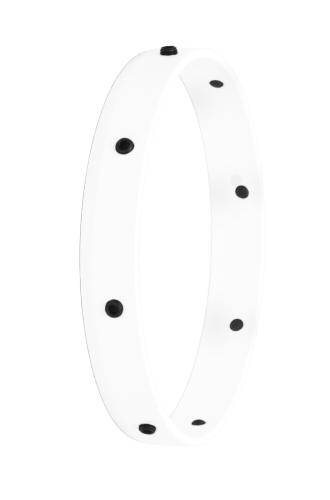

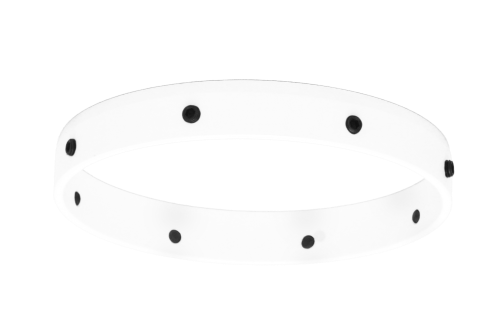

Stop Collars are used as an integral accessory to keep centralizers and other casing attachments in place on the casing string. The collar design should allow casing rotation with no or limited protrusions that can hang up on a centralizer blade. A stop collar should always have a stronger holding force than the centralizer starting force and is built to API recommended practice 10D2.

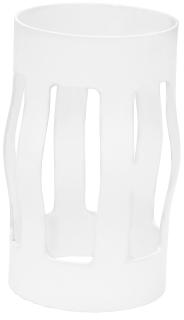

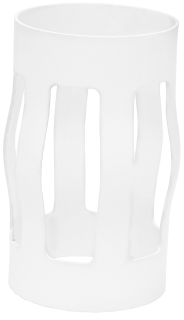

Float equipment is a key component for running casing and performing cementing operations. During cementing operations, float equipment is essential for preventing back-flow while also serving as a landing point for wiping and displacement plugs. Our float equipment and plunger valves are manufactured entirely in-house and tested to the highest quality specifications exceeding API 10F IIIC standards.

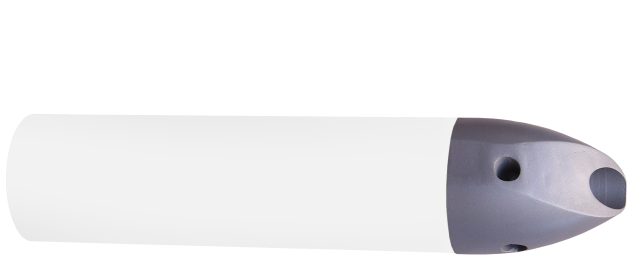

Integrity's cementing plugs are used during cementing operations for wiping the casing ID clean of drilling fluids and providing separation between mud, spacers, and cement. They also prevent over displacement of the cement slurry and indicate when the cementing job is complete. All plugs are designed to fit in conventional cementing heads and verified in-house as per API 10TR6

Control line protectors are essential components used in oil and gas wells to safeguard control lines including hydraulic control lines, electrical cables and other instrumentation from damage during installation, operation and production phases. These protectors prevent abrasion, corrosion, and mechanical stresses that control lines may face in harsh downhole environments.

ID provides specialty products such as Thread Lock Compound, API Modified High Pressure Thread Compound, Cement Baskets and Cable Wall Cleaners.