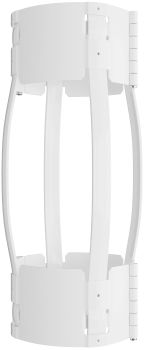

Hinged Non Weld Bow Spring Centralizer (ID-B-01)

ID's Non Weld Bow Spring Centralizers are specially designed for vertical wells wherein low starting forces as well as high restoring forces are required.The Bows of these Centralizers are heat treated in special furnace which gives it a peculiar ‘bow spring’ action.The Heat Treated bows enables these centralizer to provide best centralization as well as help in faster running of casing. The steel of these bows is a "special" made by combination or different metals to provide one of the best tensile strength as well as the "spring back" bow spring action.

In this type of Centralizers the End Collars have hinges which makes it in two halves.This enables them to be assembled at site.

The bows are locked to the End Collars via a special locking mechanism. These centralizers can be shipped in half thus reducing the freight cost.

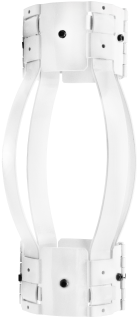

Hinged Non Weld Bow Spring Centralizer C/W Integral Stop(ID-B-04)

ID's Non Weld Bow Spring Centralizers with Integral stop have set screws so that no stop collars are required to hold the centralizers onto the pipe.These are specially designed for vertical wells wherein low starting forces as well as high restoring forces are required.The Bows of these Centralizers are heat treated in special furnace which gives it a peculiar ‘bow spring’ action.The Heat Treated bows enables these centralizer to provide best centralization as well as help in faster running of casing.The steel of these bows is a "special" made by combination or different metals to provide one of the best tensile strength as well as the "spring back" bow spring action.

In this type of Centralizers the End Collars have hinges which makes it in two halves.This enables them to be assembled at site.

The bows are locked to the End Collars via a special locking mechanism.These centralizers can be shipped in half thus reducing the freight cost.

Hinged Welded Bow Spring Centralizer (ID-B-02)

In this construction the bows of the Centralizers are welded onto the End Collars thus making it a Hinged Centralizer along with a Welded Construction.

The Bows of these Centralizers are heat treated in special furnace which gives it a peculiar ‘bow spring’ action. The Heat Treated bows enables these centralizer to provide best centralization as well as help in faster running of casing. The steel of these bows is a "special" made by combination or different metals to provide one of the best tensile strength as well as the "spring back" bow spring action.

In this type of Centralizers the End Collars have hinges which makes it in two halves. This enables them to be assembled at site.

The bows are locked to the End Collars via a special locking mechanism. These centralizers can be shipped in half thus reducing the freight cost.

Hinged Welded Bow Spring Centralizer c/w Integral Stop (ID-B-05)

This Centralizer is also available with Integral Stop (ID-B-05) wherein Set Screws are available on the End Collars. In this case the stop collars requirement is eliminated however this Centralizer would not float on the casing.

The Bows of these Centralizers are heat treated in special furnace which gives it a peculiar ‘bow spring’ action. The Heat Treated bows enables these centralizer to provide best centralization as well as help in faster running of casing.

The steel of these bows is a "special" made by combination or different metals to provide one of the best tensile strength as well as the "spring back" bow spring action.

In this type of Centralizers the End Collars have hinges which makes it in two halves. This enables them to be assembled at site.

The bows are locked to the End Collars via a special locking mechanism. These centralizers can be shipped in half thus reducing the freight cost.

At Integrity Downhole, we harness our experience to deliver downhole equipment that not only meets but exceeds the highest industry standards.

Dedicated to driving efficiency and lowering costs, our rigorously tested products ensure reliable wellbore integrity and zonal isolation.

With a commitment to integrity and excellence, ID is building a legacy.

Our unwavering dedication to quality and performance is evident in every product we create and every relationship we develop. Learn more about our journey, values, and the people behind our products.

Our float equipment, centralizers, and casing accessories are engineered to outperform through advanced design and rigorous testing.

Integrity Downhole delivers equipment that is not only dependable but also cost-effective, making us a leader in the rapidly evolving energy industry.